ASTM B117 Salt Spray Testing 1000 Hours

To demonstrate the corrosion inhibiting performance of our C-RX Umbilical Lubricant, we had a salt spray test conducted by SGS MSi according to ASTM B117 standards. These samples were placed in a salt fog chamber and testing was conducted uninterrupted for a period of 1000 hours.

Control Sample

This is the control prior to any exposure. Our samples were cut from a length of a 7 x 19 construction, 3/4″ diameter galvanized steel wire rope. This length of rope was not previously exposed to any harsh salt water environment, only the ambient conditions near the Bryan-College Station, Texas area. Our objective was to analyze the performance of C-RX in preventing the formation of new corrosion and preventing any existing corrosion from spreading.

C-RX Sample

An additional sample, cut from the same length steel wire rope, was coated with C-RX Umbilical Lubricant. This picture shows the C-RX sample prior to any exposure. The application was completed manually and not injected under pressure. This provides a baseline for the minimum level of application and its associated performance. The performance of C-RX would be further enhanced when applied with our custom lubricator.

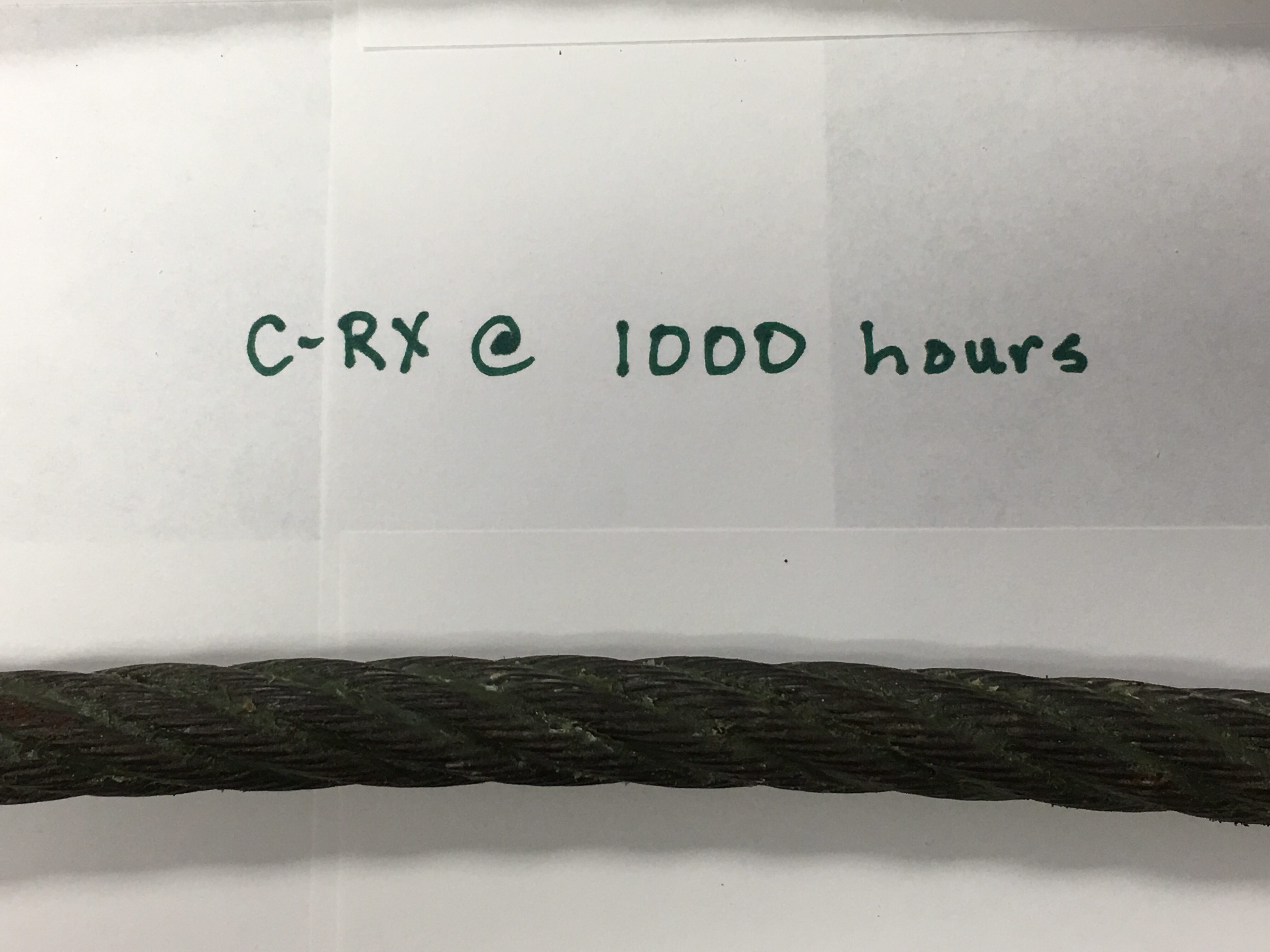

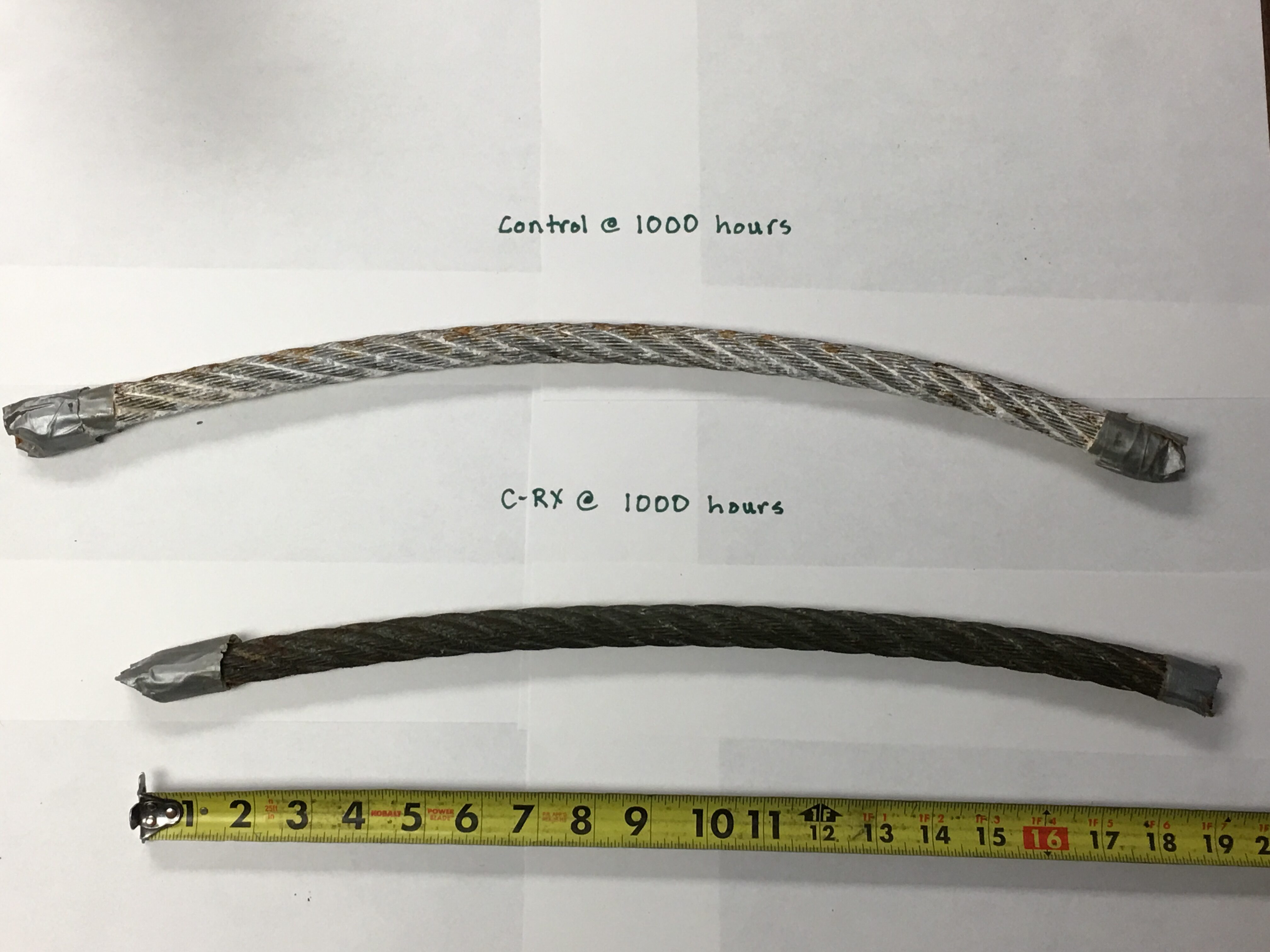

C-RX: After 1000 Hours

C-RX demonstrated outstanding performance after 1000 hours of salt spray exposure. Not only did it minimize the formation of any new corrosion, it also demonstrated its adhering characteristics by staying bonded to the sample throughout the entirety of the testing. This sample retained its limberness and remained flexible, which improves spooling characteristics. What little corrosion visible on the sample is superficial and would be easily removed by applying a new coat of C-RX under pressure with our custom lubricator.

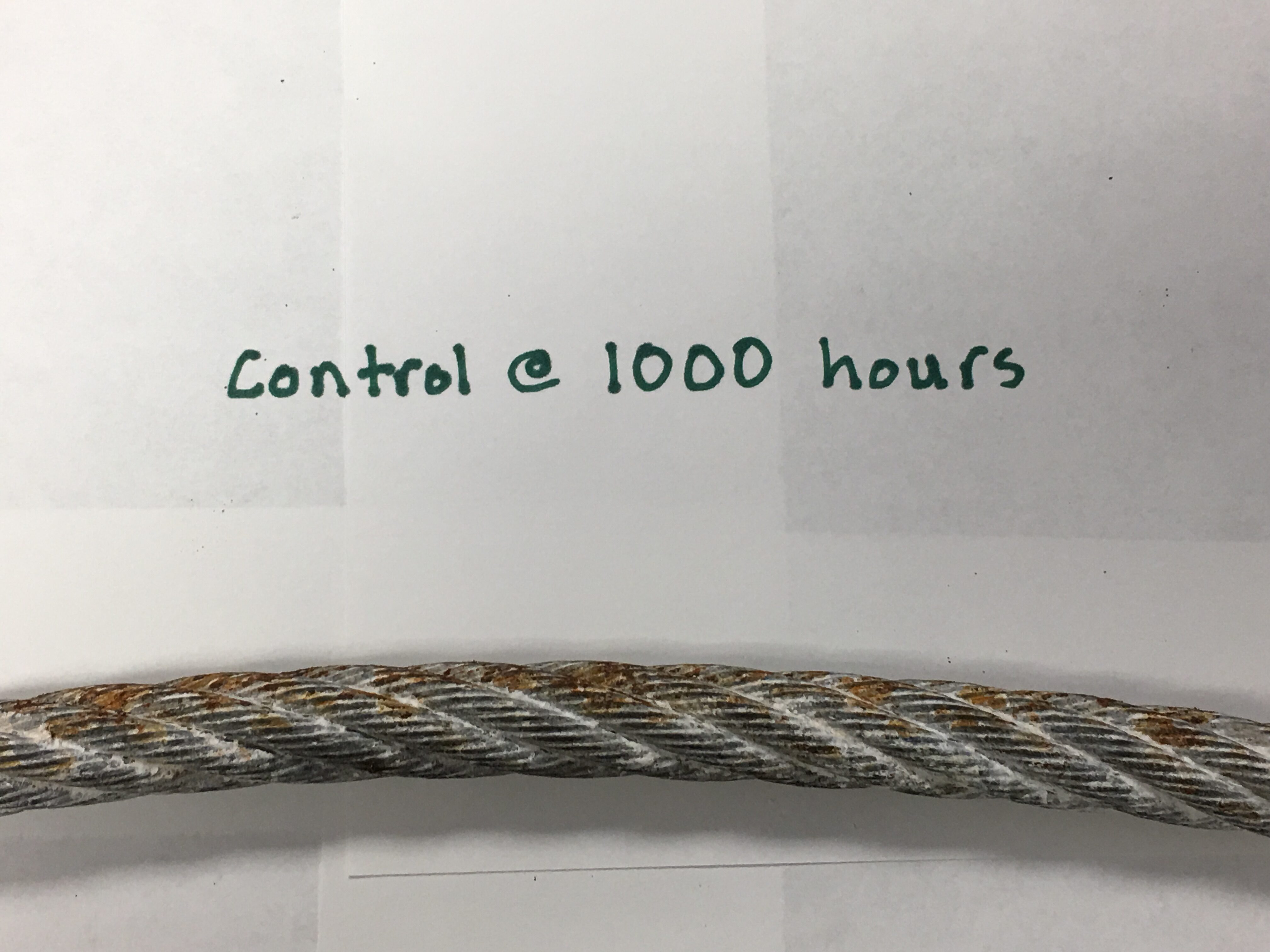

Control: After 1000 Hours

In contrast to the sample protected with C-RX, the control sample exhibited significant formation of corrosion over the majority of its surface area. Additionally, this sample lost its limberness and became very stiff. This is an indication that the corrosion is throughout the entire construction of the sample.